-

What's New?

-

Case Studies

- Bladder blisters, how it happens?

- "Can I use 50L bladder on 15G accmulator?"

- Many Users Didn’t Use Accumulator Correctly

- What Is Water Hammer and Solutions?

- Accumulator Service on German Equipment

- Do I need a stainless steel accumulator for the water service?

- Bladder Failure Cause and Prevention

- Why accumulator leaks?

- Accumulator Repair: Hydac or Headache

- Do not confuse the pressure ratings between ASME and CE/PED certificates

-

Technical & Service Guide

- Many Users Didn’t Use Accumulator Correctly

- What Is Water Hammer and Solutions?

- Countries Accepting ASME Code

- Does Bladder Have Pressure Rating?

- Do I need a stainless steel accumulator for the water service?

- Pulsation Dampener Installation & Charging Guide

- Diaphragm Accumulator Charging Instructions

- Accumulator Assembly Instructions

- Bladder Failure Cause and Prevention

- Accumulator Charging Guide

- Bladder Buying & Storage Guide

- Why accumulator leaks?

- Accumulator Repair: Hydac or Headache

- Do not confuse the pressure ratings between ASME and CE/PED certificates

- Show all articles (4) Collapse Articles

What Is Water Hammer and Solutions?

What Is Water Hammer?

Water hammer is a common phenomenon that occurs in the pipeline system using control valves. It is the result of a pressure surge, or high-pressure shockwave that propagates through the pipeline system when a fluid in motion is forced to change direction or stop abruptly. This shockwave is also commonly referred to as a hydraulic shock or hydraulic surge.

Water hammer normally occurs when an open valve suddenly closes, causing the water to slam into it, or when a pump suddenly shuts down and the flow reverses direction back to the pump.

This pressure wave can cause major problems, from noise and vibration to pipe rupture or collapse, leakage, as well as downtime and maintenance.

There are many effective methods for preventing water hammer such as reducing the fluid pressure with regulators, lowering the fluid speed, applying slowly closing valves, using shorter pipe lengths or adding elbows, loops, etc.

However, when a pipeline system is already designed or in the use, the most common solution is to add a proper sized surge suppressor tank.

Our RPK series low pressure surge suppressors PULSEKUSHONTM are especially designed for the water hammer solutions, which has been widely used in the industries with surge control requirements such as refinery, airport, oilfield, water service, etc.

Check our product page below.

Water Hammer Valve Closing Time

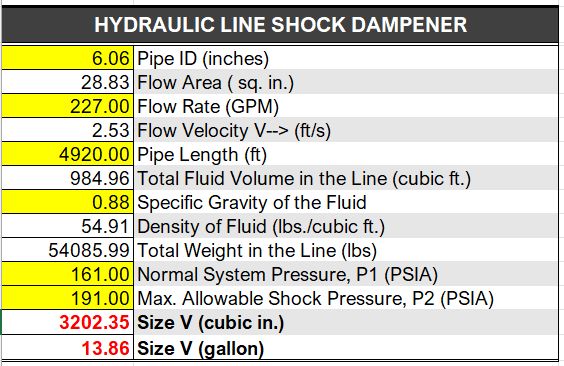

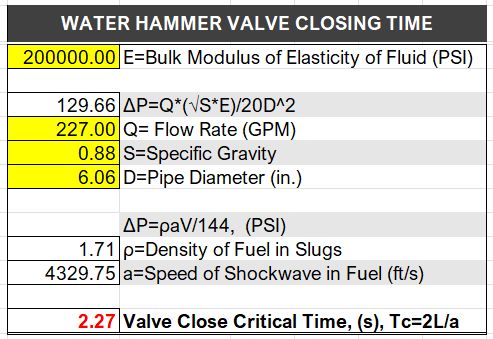

In addition to above solutions, water hammer effects can be controlled, to some extent, by the valve closing time. Knowing the valve critical closing time can help minimize the water hammer effect in the system. We use the following calculation forms to determine the surge suppressor size and the valve critical closing time. (yellow background data is for the known values; white background data is for the calculated values)

Bulk Modulus for some common fluids:

How to Use the Valve Critical Closing Time?

The valve critical closing time is the closing time when water hammer happens. In another word, the operator needs to close the valve with a longer time to avoid the water hammer effect.

From this point, a faster critical closing time makes it easier to control the water hammer effect from the closing valve because the operator has reasonable longer time to close the valve. In contrast, if the critical closing time is long (e.g. in several seconds), the normal valve closing time is faster, making the water hammer effect.

From the calculation form and the equation derivatives, we can see:

The valve critical closing time Tc is only determined by the factor of Pipe Length (L) and the Fluid Properties (E, S and r). It is not related to Flow Rate/Speed (Q) or the Pipe Diameter (D).

Since the fluid is already determined by the application and cannot change, the valve critical closing time Tc actually is determined by the pipe length only in practice. The longer the pipe length is, the longer the valve critical closing time is, or the easier occurrence of water hammer.

Need Technical Help?

Contact us if you have questions or need technical support on this topic or product..