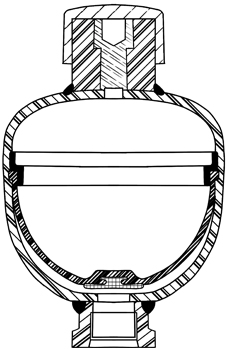

Diaphragm Accumulators

Pulsation Dampeners

Carbon Steel • Stainless Steel

Why Use Diaphragm Accumulators

Diaphragm accumulators provide an affordable means of enhancing the performence of a hydraulic system. They are suitable for storing energy under pressure, absobing hydraulic shocks, and dampening pump pulsation and flow fluctuations with the following characteristics:

- Improves system efficiency

- Supplement pump flow

- Supplies power in emergency

- Compensates for leakage

- Absorbs hydraulic shocks

- Works well with water, low lubricity fluids

- Very contamination tolerant

- Cost effective

- Compact, lightweight

- Safety, non-repairable design

- Very quick response

Specifications

Materials

- Shell- high strength alloy steel; stainless steel

- Ports- steel, stainless steel

- Gas Valve Stem- steel, stainless steel

- Diaphragms- Nitrile (NBR); FKM (Viton); Hydrin (ECO)

Maximum Flow Rates

Max. Compression Ratio

- (max. working pressure/precharge pressure)

- 8:1 on 0.16 liter through 1.4 liter;

- 4:1 on 2 liter and larger

Available Options

- Gas Valve- standard metric M28X1.5

- Fluid Port- various custom sizes, NPT or metric

- Diaphragm Materials- standard Nitrile (Buna-N) (14oF-200oF/-100C-93oC); Hydrin (ECO) (-40oF-200oF/-40oC-93oC); FKM (Viton) (-10oF-400oF/-23oC-204oC)

-

Shell-High strenth alloy steel or stainless steel, welded or repairable.

-

Diaphragm-Flexible diaphragm to separate the gas and fluid. Available compounds are Nitrile (NBR); Viton (FKM) and Hydrin (ECO). Check the rubber material compatibility.

-

Button-The button closes the fluid port when the accumulator is fully discharged to prevent diaphragm extrusion.

-

Fluid Port-Various leak-free fluid port connections are available to order, SAE, NPT and metric sizes.

-

Gas Valve-Standard metric M28X1.5 gas valve for high pressure leak-free charging.