How to Size An Accumulator?

Accumulators can be used in many different applications, which are related to different equations for calculation. Accumulator calculations are based on the principle of thermodynamic laws:

P1V1=P2V2, Isothermal Condition (Temperature is constant, heat transfer occurs. This is normally for a slow change of gas volume); or,

P1V11.4=P2V21.4, Adiabatic Condition for Nitrogen (no heat transfer. This is for a rapid change of gas volume and temperature changes).

We are giving the calculations below for the most popular applications.

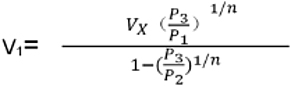

AUXILIARY POWER SOURCE

V1=size of the accumulator required in cubic inches;

P1=Accumulator pre-charged pressure (psi);

P2=System maximum operating pressure (psi);

P3=System minimum pressure (psi);

VX=Volume of fluid required (in3);

N=constant 1.4 for Nitrogen

Adiabatic Calculation: select if gas volume changes rapiadly, while temperature changes.

PUMP PULSATIONS DAMPENER

A=Area (square inches) of pump cylinder bore;

K=Constant for particular type of pump (see the table below);

L=Length of piston stroke (in); (or AL=pump displacement in3);

P1=Minimum system pressure or accumulator pre-charge pressure (psi);

P2=System mean pressure (psi);

P3=Maximum system pressure (psi);

N=Constant 1.4 for Nitrogen

- Pulsation dampener calculation is typically for piston type pumps, it may not be used for other types of pump.

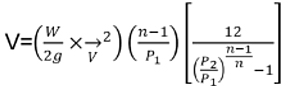

HYDRAULIC LINE SHOCK DAMPENER

Another major application of accumulator as surge control device is in the suppression or reduction of repeated high pressure pulsations or hydraulic line shock, or so-called “Water- Hammer”. This is caused by the sudden stoppage or deceleration of fluid flowing at high velocity in a pipe line. The rapid pressure or high pressure pulsations or surges produced in the system may cause pump line failure, breaks in the lines, external leakage and severe damage to valves and instruments.

W=Total weight (lbs) of fluid in the pipe line, this is to be calculated by the given pipe I.D, pipe length and fluid density;

v2=Flow Rate Q (GPM)/Pipe flow area A (in2);

P1=System normal pressure (psi)

P2=System maxium allowable shock pressure (psi);

n=Constant 1.4 for Nitrogen

If the system has different pipelines, calculate each horizontal pipeline individually using the tool and sum the results together.

WATER HAMMER VALVE CLOSING TIME

Water hammer is a common harmful phenomenon for pipelines. It is caused mainly by closing the control valve in the sytem to create the pressure surge or shock wave.

Our PulseKushon surge surpressors are specially designed for the pipeline water hammer preventions that are widely used in airport, wate & fuel system, refinery, etc.

Closing the control valves slowly can help alleviate the water hammer problem. In such case, the valve’s critical closing time for water hammer is calculated. In operation, close the valves slower (with longer time) than it’s critical closing time to prevent water hammer and protect the fittings, devices and parts in the system.

Read our technical article of water hammer and solutions in detail.

Accumulator Sizing Form

Download the Accumulator Sizing Form, fill it out and send back to us, we'll calculate the size of the accumulator for your application.

DOWNLOADAccumulator Technical Help

Need special help on the new applications? Contact us for the quick and professional assistance.

CONTACT US ![]()